▶ Please Click Here to Review More Details!!

Main Features

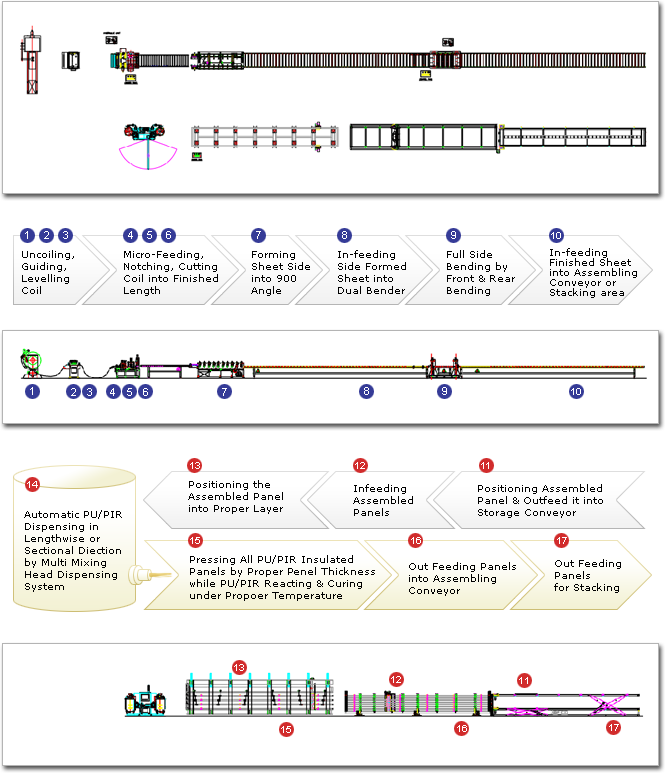

For Freezing / Refrigeration Panels like Cold Store Panels Production, We, TradeBelt Consortium proposes the Developed SemiContinuous Production Line from Traditional Discontinuous Production Line-up.

- the Worldwide Patented Multi-Layer Vertical Hot Press Line of the Most Advanced Production Mechanism for Higher Production Speed, the Greater Production Capacity, the lowest Panel Movement Error, Lower Manufacturing Cost incl. Labour & Electric Cost.

- the Developed Version of PIR/PU High Pressure Injection Line with Cross Dispensing Robot for Higher Production Speed, Uniform Panel Core Quality and Lower Labour Cost by the Synchronized Upper Skin Feeding System.

- the Very competitive price on Roll Forming Line for full-side bending Panel of Cold Store Refrigeration Panel by Cast Iron Steel Structure Stand from our long experience on this mechanism.

The PE Cam Lock Assembly with PU/PIR Side Brim is the Newest Version of Cold Store Refrigeration Panel Connection. If interested, We, TradeBelt Consortium will show and guide you to the new Brim system and Its Production Line for your market.

In case of Production Speed, There are 2 Options such as Automatic Crosswise PU/PIR Injection System and Manually Sectional PU/PIR Injection System. Automatic Crosswise PU/PIR Injection System is Much Higher in Production Speed but about 10% Higher in Initial Cost than Manually Sectional PU/PIR Injection system.

In order to Customize our Production Line for your desired production speed, we have to finalize the necessary PU/PIR Foam Reaction Time before Designing our Production Line.

- the Worldwide Patented Multi-Layer Vertical Hot Press Line of the Most Advanced Production Mechanism for Higher Production Speed, the Greater Production Capacity, the lowest Panel Movement Error, Lower Manufacturing Cost incl. Labour & Electric Cost.

- the Developed Version of PIR/PU High Pressure Injection Line with Cross Dispensing Robot for Higher Production Speed, Uniform Panel Core Quality and Lower Labour Cost by the Synchronized Upper Skin Feeding System.

- the Very competitive price on Roll Forming Line for full-side bending Panel of Cold Store Refrigeration Panel by Cast Iron Steel Structure Stand from our long experience on this mechanism.

The PE Cam Lock Assembly with PU/PIR Side Brim is the Newest Version of Cold Store Refrigeration Panel Connection. If interested, We, TradeBelt Consortium will show and guide you to the new Brim system and Its Production Line for your market.

In case of Production Speed, There are 2 Options such as Automatic Crosswise PU/PIR Injection System and Manually Sectional PU/PIR Injection System. Automatic Crosswise PU/PIR Injection System is Much Higher in Production Speed but about 10% Higher in Initial Cost than Manually Sectional PU/PIR Injection system.

In order to Customize our Production Line for your desired production speed, we have to finalize the necessary PU/PIR Foam Reaction Time before Designing our Production Line.